Bearings are the most essential element of industrial machines and motors. Bearings minimise friction between two rotating and linear pieces of equipment, increasing speed and efficiency. Bearings are classified based on their use, operation, load direction to equipment, and movements. Let us talk about the bearing category.

Roller Bearing

Roller bearings are another type of common bearing that is usually utilized in the industrial sector. It can carry more radial load than other standard types of bearings. Between the gaps of two radial faces, a roller bearing was utilised instead of a ball. Whereas a ball bearing produces point contact, this bearing roller makes line contact. Because of the roller, it gives greater precision and performance over time.

Roller bearings are preferred for:

– Operation at high speeds.

– Minimal lubrication is required.

– Longer lifespan.

Ball Bearing

Ball bearings are the most frequently used and popular form of bearing. This type of bearing can withstand both thrust and radial loads. It lowers rotating friction and improves application performance. Ball bearings have two races that contain balls that transmit loads. Because of the tiny contact surface between races and balls, it has a reduced load capacity bearing. It is less costly and can be constructed of stainless steel or chrome steel. In hybrid bearings, ceramic balls and metal races are employed.

Thrust Bearing

Thrust bearings are rotary bearings that allow single or multiple elements to rotate. They are developed specifically for axial loads. There are several types of thrust bearings available for use in industrial and automotive applications.

We reviewed the two basic types of thrust bearings in this section.

– Roller thrust bearing.

– Ball thrust bearing.

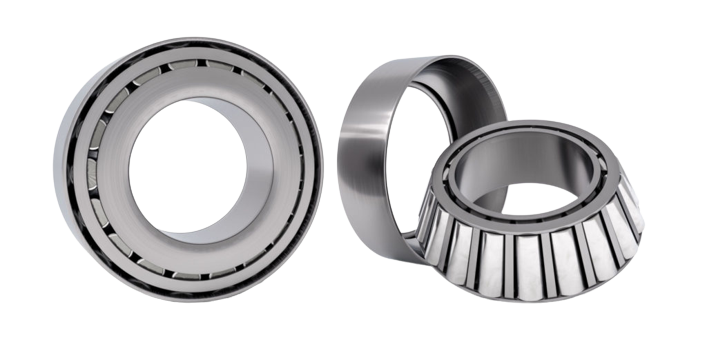

Tapered Roller Bearing

Tapered roller bearings can withstand high radial and thrust loads. They are made up of a cup and cone assembly, inner and outer rings, and a tapered roller. They are commonly used in automotive hubs because they can withstand a wide range of loads. They are most typically utilised in heavy duty applications where moderate speeds and durability are required. The bearing’s contact angle varies according to the loading ratio. Tapered roller bearings have a long life, are dimensionally stable, and have a strong steel cage.

Needle Roller Bearing

A needle roller bearing is surrounded by a cylindrical roller. It is most typically found in the motorcycle’s chain drive system, crankshaft, and chassis, allowing for simple movement with the ease of loads. The needle roller bearing size is small and takes up little space when fitted. This bearing can withstand large radial loads. This bearing makes the machinery smaller and lighter.

Linear Bearing

Linear bearings are intended to give linear or free motion in only one direction. They fit into the circular or square rail. These bearings are often found in automotive and industrial machines. They are capable of carrying huge weights.

They are available in two varieties:

– Roller slides.

– Ball slides.

Ball Bush Bearing

A ball bush bearing is a type of bearing that has a cylindrical shaped housing with a pair of ball arrangements within. It only enables movement in one direction. It can be flange mounted, in which case the flange strongly grips the bearing. The application dictates whether flange or round rail is fitted. It is most widely utilised because of its low frictional resistance and improved movement precision.